Ethane Cracker Process Flow Diagram

Ethane must be cracked to make ethylene 26. Between a variety of processes the thermal crack ing of hydrocarbons in the presence of steam steam cracker is mostly used.

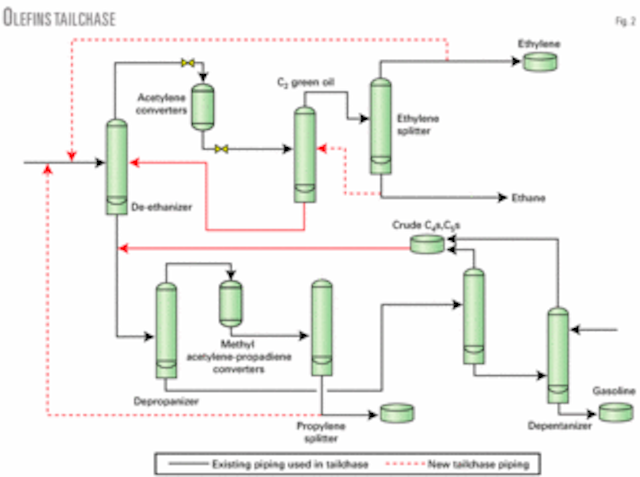

New Catalytic Process For Production Of Olefins Oil Gas Portal

The process can include a premixed h 2 addition in the feed.

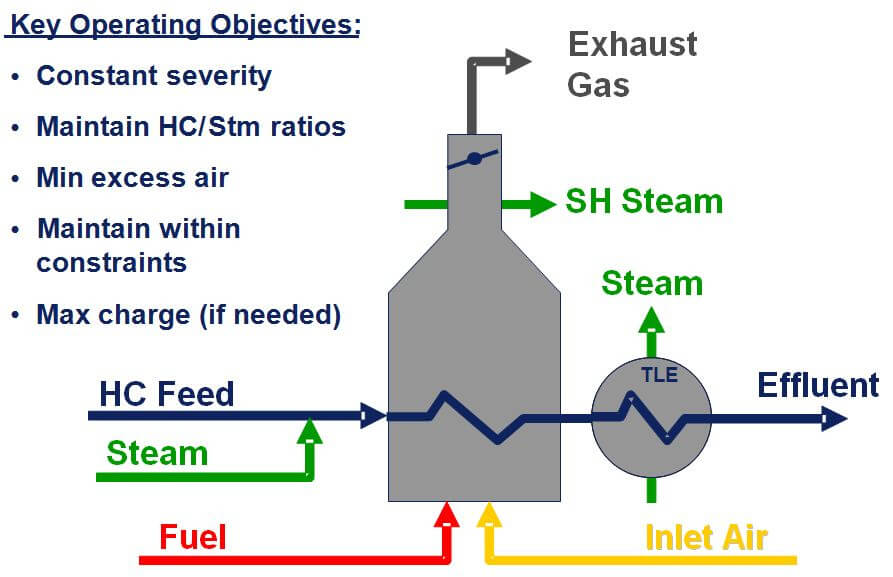

Ethane cracker process flow diagram. In modern crackers where the furnace process is highly optimized a more accurate control is required. Dilution steam can also be used for decoking the furnace making good rangeability a. The cracking process involves breaking up the carbon and hydrogen molecules and rearranging them.

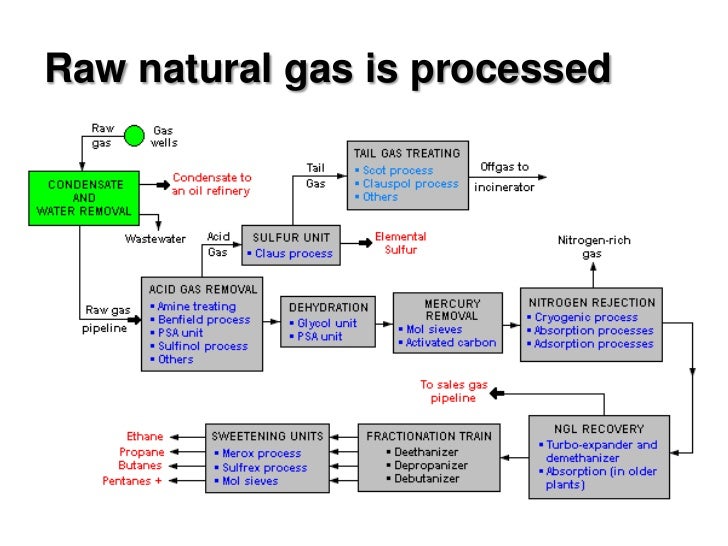

Acid gas removal dehydration fractionation train hydrogenation reactor an ethylene splitter and steam cracking refer to appendix b for the process flow diagram. Control systems the criticality of the steam flow control system can vary. Initially an ethane propane mixture is fed to furnaces in which under high severity conditions it is cracked forming ethylene propylene and other byproducts.

Regardless of the process type all plants require process analytical equipment to collect reliable and accurate process data for process con trol product quality and plant safety. The new process alternative to convert ethane to ethylene is a short contact time reactor a few milliseconds in which the reaction takes place in the presence of a foam monolith of alumina supported pt sn catalyst. Carbon dioxide must first be removed from the inlet shale gas in the acid gas removal section.

The ethane crackers fuel consists of a mixture of recycled tail gas hydrogen rich and natural gas methane with a heating value of 523 btuscf. This process diagram shows an ethylene production process via the cracking of an ethane propane mixture cracking and quenching. Linde 713 873 1708.

Liquids ethane and lpg and heavy liquids ie naphtha and gas oils. Advances in ethane cracking. Full range naphtha frn is thought of as any hydrocarbon that boils in the.

Poor performance of the steam supply valve can lead to excessive fouling of the cracker. Cracking is accomplished by heating ethane to greater than 800c 1500f in the cracker furnace. The process description and process flow diagrams given in the report are based on an ethanepropane feedstock.

Normal operation assumes five furnaces continuous operation and one furnace on hot stand by or decoking operations. Steam cracker 170 mw heat duty modeled as 2 100mw separate pyrolysis furnaces each furnace 100 mw capacity operates at 80 capacity. Natural gas liquids ngls are composed essentially of ethane propane and butanes.

The proposed design consists of six main sections.

Mathematical Model For Ethane Pyrolysis In An Industrial

New Catalytic Olefins Technology

Flare Minimization Practices Improve Olefins Plant Start Ups

Flare Minimization Practices Improve Olefins Plant Start Ups

Simulation And Optimization Of The Ethane Cracking Process

Simulation And Optimization Of The Ethane Cracking Process

Shale Gas To Ethylene G2 Processdesign

Shale Gas To Ethylene G2 Processdesign

Efficiently Cracking Hydrocarbons In Ethylene Furnaces

Efficiently Cracking Hydrocarbons In Ethylene Furnaces

Non Catalytic Ethane Cracking Using Concentrated Solar

Non Catalytic Ethane Cracking Using Concentrated Solar

Typical Flow Diagram For A Naphtha Steam Cracker Figure Was

Typical Flow Diagram For A Naphtha Steam Cracker Figure Was

Ethylene Production From Tennessee Fracked Natural Gas

Process Economics And Safety Considerations For The

Miss Rahimah Binti Othman Ppt Download Ethylene Production

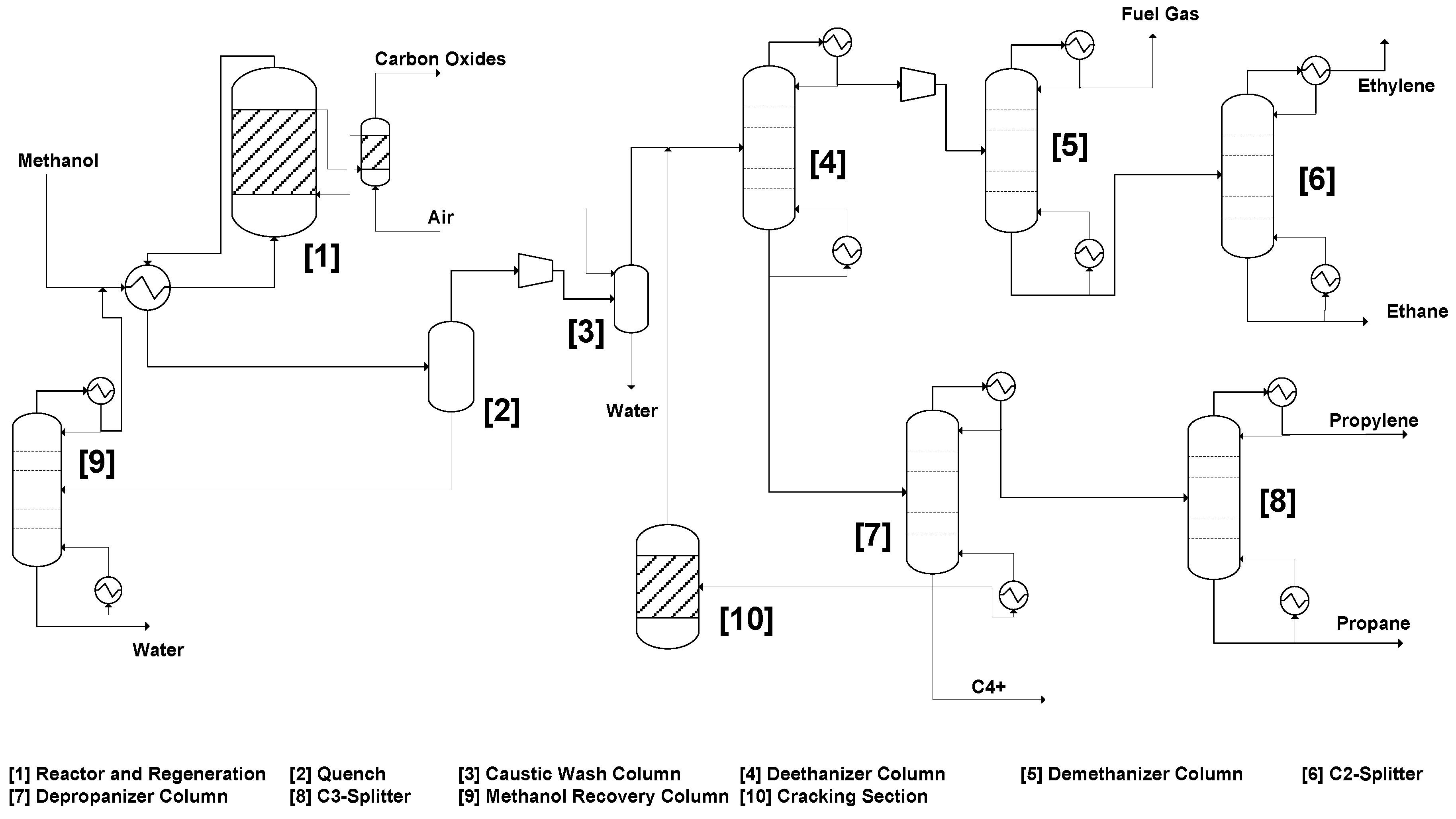

Techno Economic Performance Of The Coal To Olefins Process

Techno Economic Performance Of The Coal To Olefins Process

Energy Flow In A Typical Naphtha Steam Cracker With The Fuel

Energy Flow In A Typical Naphtha Steam Cracker With The Fuel

Schematic Of Ethane Steam Cracking Furnace Download

Schematic Of Ethane Steam Cracking Furnace Download

Integrated Fcdh Reactor System With Ethane Cracker

Integrated Fcdh Reactor System With Ethane Cracker

Cracking And Related Refinery Processes

Olefins Markets Innovations Ptt Global Chemical Public

Olefins Markets Innovations Ptt Global Chemical Public

Processes Free Full Text A Techno Economic Comparison

Processes Free Full Text A Techno Economic Comparison

12 3 Types Of Coal Derived Chemicals Netl Doe Gov

12 3 Types Of Coal Derived Chemicals Netl Doe Gov

Fluid Catalytic Cracking Process Download Scientific Diagram

Fluid Catalytic Cracking Process Download Scientific Diagram

Detailed Modelling And Optimisation Of An Ethylene Plant

Shale Gas To Ethylene G1 Processdesign

Shale Gas To Ethylene G1 Processdesign

Belum ada Komentar untuk "Ethane Cracker Process Flow Diagram"

Posting Komentar