Ppap Process Flow Diagram

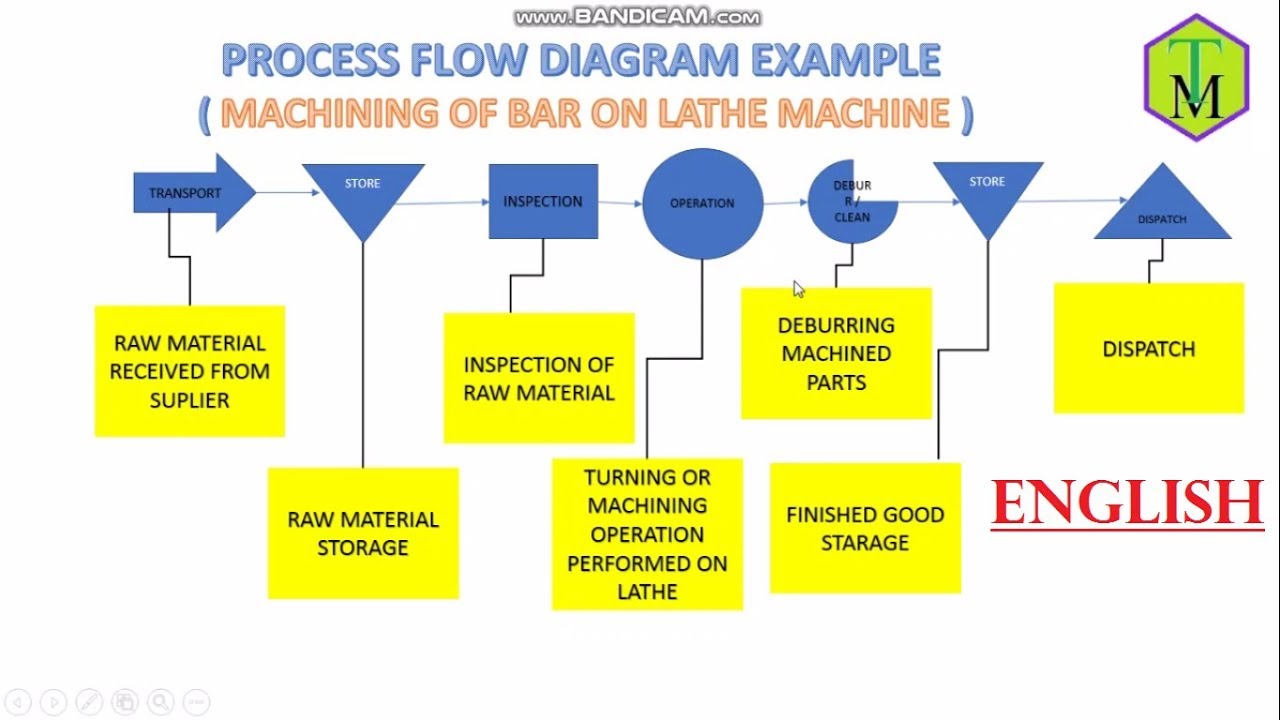

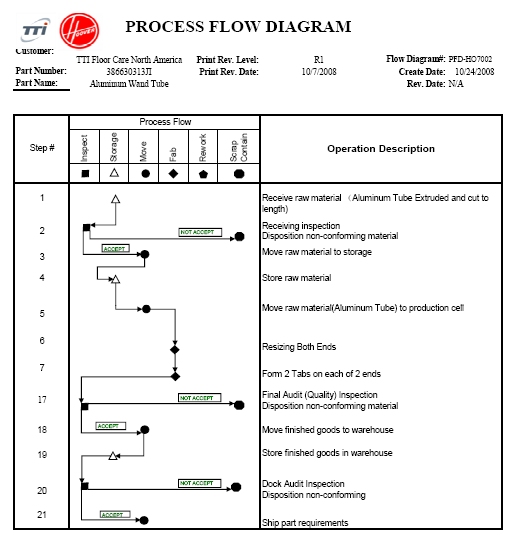

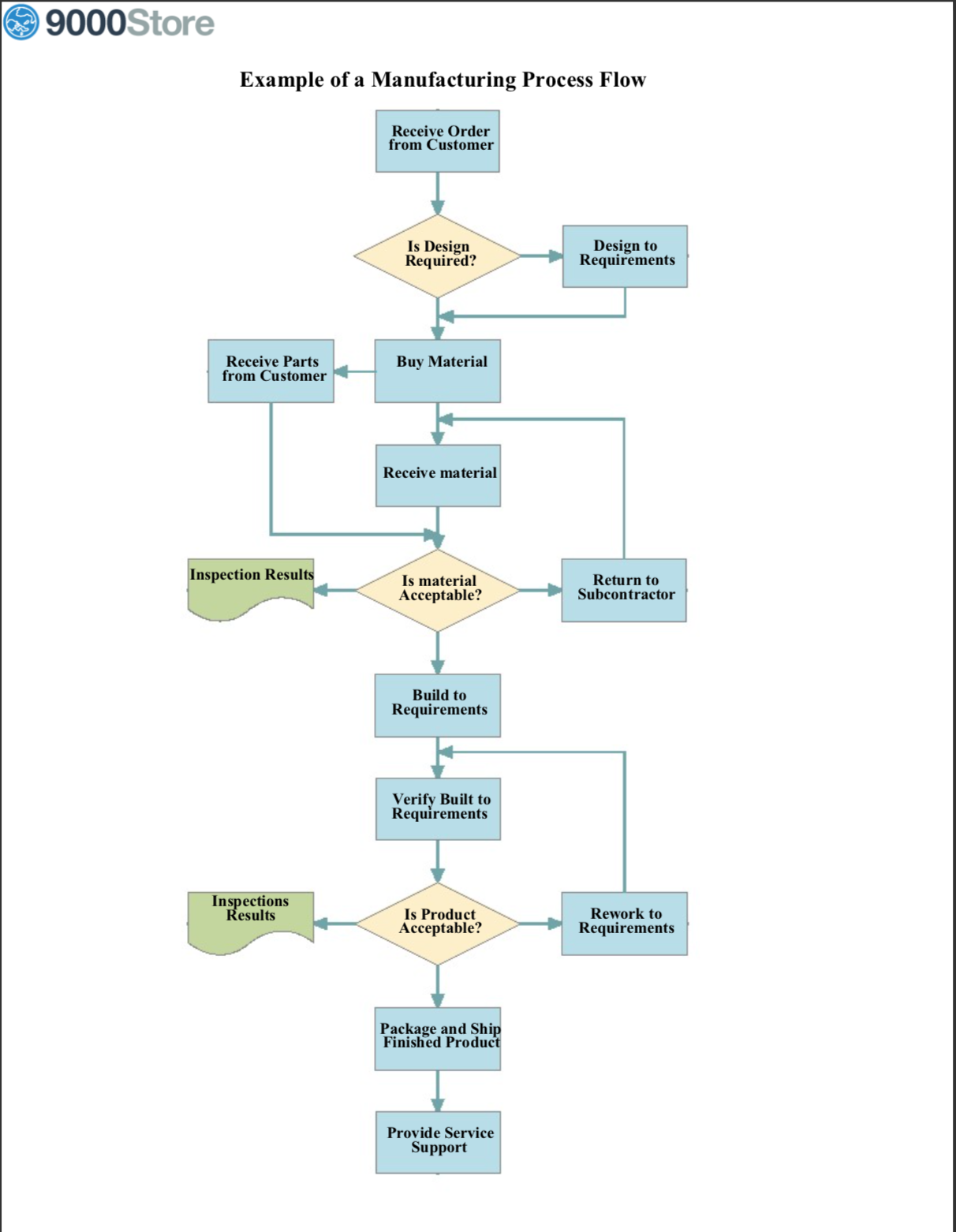

The purpose of the process flow diagram is to document the steps required in the manufacturing of the part. The purpose of the ppap is to ensure that the customers design has been understood by the supplier and to prove that the supplier is capable of producing good parts consistently.

Ppap Process Flow Chart Arenda Stroy

Ppap Process Flow Chart Arenda Stroy

Pfmea a copy of the process failure mode and effect analysis reviewed and signed off by supplier and customer.

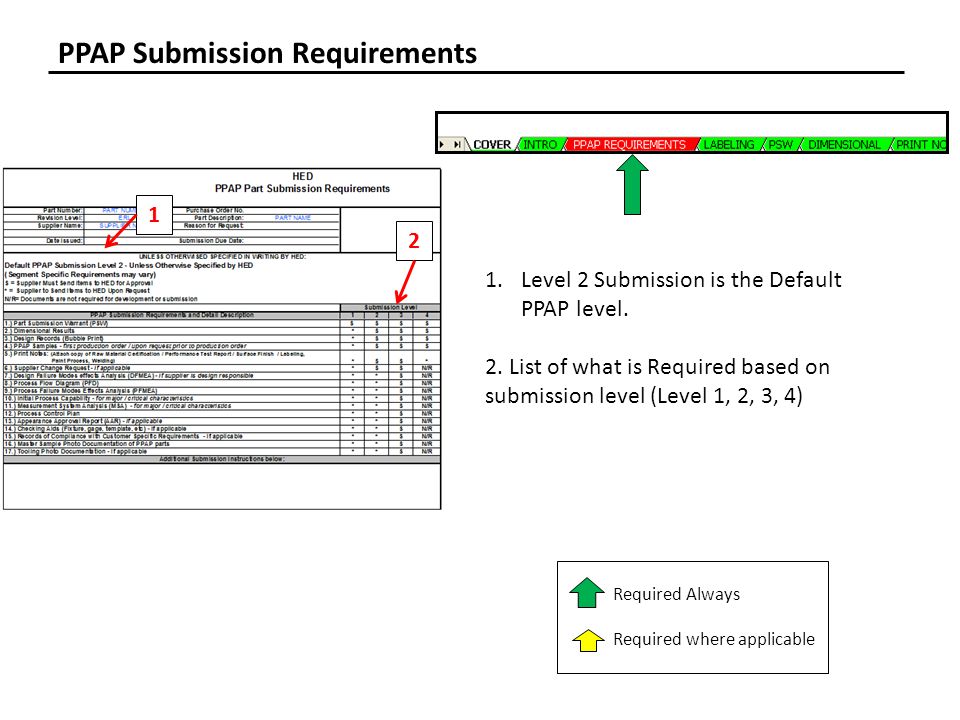

Ppap process flow diagram. The pfmea follows the process flow steps and indicates what could go wrong during the fabrication and assembly of each component. On this site you will find lots of information on building or updating a complete ppap. What is production part approval process ppap ppap defines the approval process for new or revised parts or parts produced from new or significantly revised production methods.

The main process steps must match both the process failure mode effects analysis and the. Process flow diagram also known as a process flow chart shows the document and clarifies all steps required in the manufacturing of the part in question. The ppap process consists of 18 elements that may be required for approval of production level parts.

It includes incoming material assembly test rework and shipping. This site includes ppap information different level of ppap that can be requsted examples of submissions training providers and a checklist to make sure you your production part approval process is correct. Process flow diagram a copy of the process flow indicating all steps and sequence in the fabrication process including incoming components.

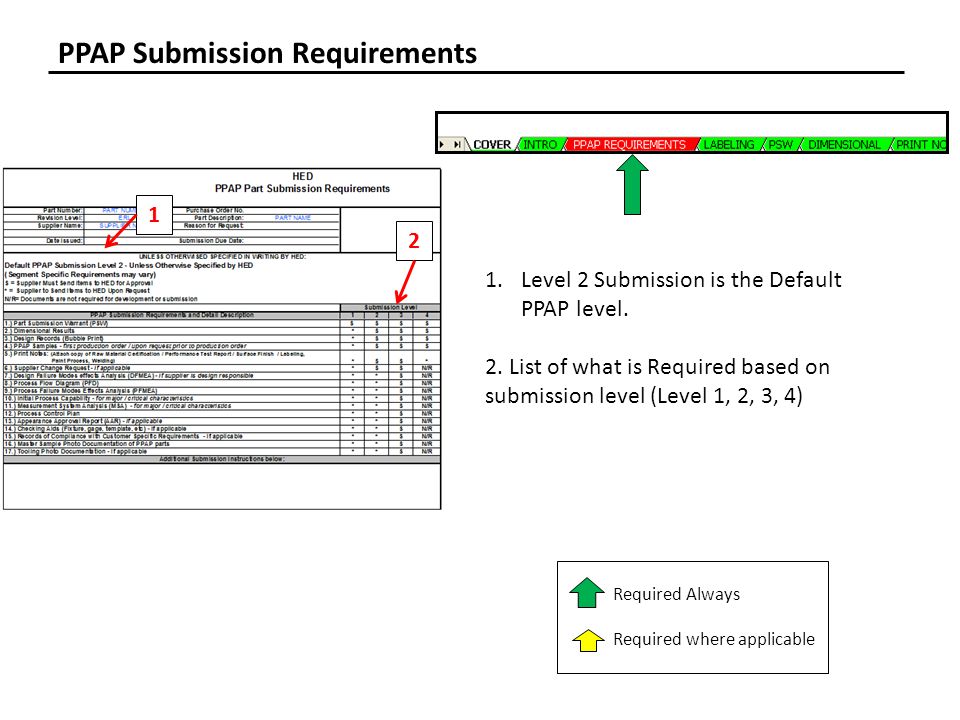

A diagram can show a process hierarchy or other relationships. Not all of the elements are required for every submission. The production part approval process ppap is a framework of requirements used in the automotive supply chain to establish confidence in suppliers and their manufacturing processes.

The process flow diagram outlines the entire process for assembling the component or final assembly. You can use autoshapes and arrows the flowchart shapes with connectors in the lines category in powerpoint 2007. Part submission warrant psw design records authorized engineering change note documents.

The process flow diagram must match both the control plan and the process failure mode and effects analysis pfema. It includes incoming material assembly test rework and shipping. Otherwise in the connectors category or the smartart feature of 2007.

Aiag Process Flow Diagram Eaton Ppap Specification Technical

Aiag Process Flow Diagram Eaton Ppap Specification Technical

Process Flow Diagram Basics Schematic Wiring Diagram

Process Flow Diagram Basics Schematic Wiring Diagram

What Is Ppap Qualitytrainingportal

What Is Ppap Qualitytrainingportal

Process Flow Diagram Pfd In English Ppap Document 7 Qc Tool

Process Flow Diagram Pfd In English Ppap Document 7 Qc Tool

Ppap Documents What Is Ppap Production Part Approval

Ppap Documents What Is Ppap Production Part Approval

Quality Assurance Measures For Procurement Of Purchased Parts

How To Make A Flowchart In Excel Payroll Process Flow Chart

Process Flow Diagram Aiag List Of Wiring Diagrams

Process Flow Diagram Ppap Group Electrical Schemes

Process Flow Diagram Ppap Group Electrical Schemes

Ppap Process Flow Diagram Symbols Kaskader Org

Process Flow Diagram Aiag List Of Wiring Diagrams

Process Flow Diagram Aiag Wiring Diagram Directory

Process Flow Diagram Aiag Wiring Diagrams Folder

Process Flow Diagram Aiag The Best Place To Get Wiring

Process Flow Diagram Aiag The Best Place To Get Wiring

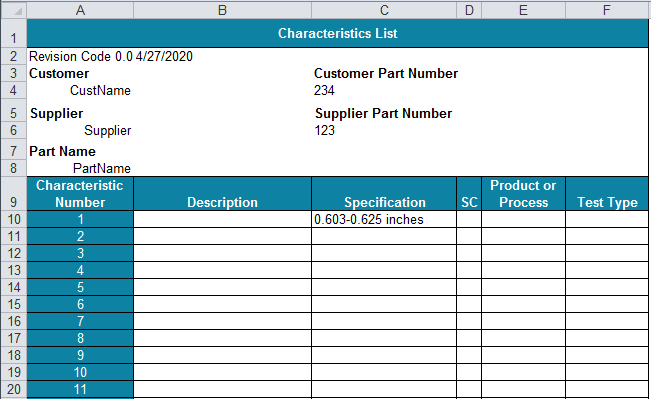

Ppap Forms In Excel Ppap Templates Aiag 4th Ed Compatible

Ppap Forms In Excel Ppap Templates Aiag 4th Ed Compatible

Process Flow Diagram Aiag List Of Wiring Diagrams

Process Flow Diagram Aiag List Of Wiring Diagrams

Process Flow Diagram Ppap Wiring Diagram

Process Flow Diagram Ppap Wiring Diagram

Process Flow Diagram Ppap Wiring Diagram

Process Flow Diagram Ppap Schematic Diagram

Process Flow Diagram Ppap Schematic Diagram

Ppap Requirements Training Ppt Video Online Download

Ppap Requirements Training Ppt Video Online Download

Process Flow Diagram Aiag Wiring Diagram

Process Flow Diagram Aiag Wiring Diagram T3

Pdf Production Part Approval Process Ppap Jaimit Gandhi

Pdf Production Part Approval Process Ppap Jaimit Gandhi

Process Flow Diagram Basics Wiring Diagram Oline For Everyone

Process Flow Diagram Basics Wiring Diagram Oline For Everyone

Belum ada Komentar untuk "Ppap Process Flow Diagram"

Posting Komentar